Best Practices for Displaying Forklift Truck Safety Signs in Industrial and Storage Facility Settings

The implementation of efficient forklift vehicle safety signs is important in industrial and storehouse settings, where the risk of crashes can substantially impact both personnel and operations. What details methods can organizations embrace to ensure their safety and security signs genuinely serves its objective?

Significance of Safety And Security Signs

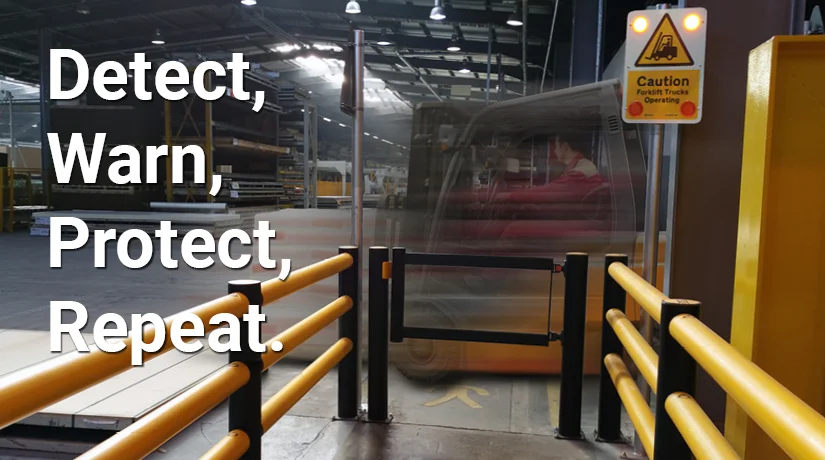

The value of safety signage in environments where forklift vehicles run can not be overstated, as these signs play an essential duty in stopping crashes and making sure the safety of personnel. Reliable security signage functions as an essential communication tool, conveying essential info concerning potential threats related to forklift procedures. This includes cautions concerning pedestrian zones, rate limits, and designated forklift courses, which are necessary for keeping an arranged and secure working environment.

Appropriately presented safety and security indications can improve situational awareness amongst employees, reminding them of the risks involved in their surroundings. They offer clear instructions on risk-free practices, such as using appropriate individual protective tools (PPE) and sticking to operational standards. Moreover, safety and security signage adds to conformity with governing needs, aiding organizations avoid charges and advertise a society of safety - Forklift Truck Safety Signs.

In enhancement to their precautionary function, safety and security indicators foster a feeling of accountability amongst employees. When employees understand safety and security procedures and the prospective effects of neglecting them, they are a lot more most likely to take positive procedures to shield themselves and their coworkers. As a result, purchasing high-quality safety signage is crucial for any office where forklift vehicles function.

Secret Presence Factors

Effective presence is paramount in guaranteeing the safety and security of both forklift drivers and pedestrians in active workplace. To attain this, numerous crucial presence variables have to be thought about when designing and placing security indicators.

First, the size and typeface of the message on the indication play a vital function. Larger font styles boost readability from a range, allowing people to swiftly understand the message. In addition, the usage of strong and clear typefaces can dramatically boost readability under numerous illumination problems.

Effective Placement Techniques

Sign placement substantially influences their performance in communicating security messages within forklift operations. To make best use of visibility and comprehension, signs must be tactically positioned in locations where forklift activity prevails. Key areas include crossways, blind areas, and near loading and dumping areas, where operators and pedestrians interact frequently.

Elevation is another crucial variable; signs should be put at eye degree to guarantee they are quickly seen by both forklift operators and ground workers. In addition, utilizing contrasting colors and clear graphics will certainly enhance exposure, particularly in low-light conditions or high-traffic locations.

Consider the flow of web traffic when identifying positioning. Indications must be placed to direct operators safely and efficiently through the office, decreasing the threat of accidents. Moreover, regular assessments must be performed to make sure that indications continue to be unobstructed by tools or supply, as shifting designs can diminish their performance.

Integrating feedback from workers pertaining to indication positioning can additionally cause renovations. Involving personnel in this procedure fosters a culture of security and recognition, ultimately adding to an extra protected job environment. By implementing these efficient positioning techniques, companies can boost communication and adherence to security methods.

Conformity With Laws

Making sure conformity with policies is vital for preserving a secure workplace in forklift operations. Regulatory bodies such as the Occupational Safety and Health Management (OSHA) and the American National Standards Institute (ANSI) establish standards that dictate the proper use safety indicators. Adherence to these laws not just promotes safety yet additionally minimizes the danger of penalties and lawful responsibilities.

Forklift security signs have to be plainly visible, legible, and purposefully put according to regulatory needs. These indications ought to make use of standardized symbols and color codes to communicate essential information successfully. Yellow suggests caution, while red signals danger, making sure that employees can promptly interpret the signs in high-stress scenarios.

Organizations should perform normal audits to validate that all safety signs fulfills best site present lawful my sources standards. By guaranteeing that forklift security signs adhere to mandated standards, business promote a society of safety and security recognition amongst employees, thereby improving general work environment security and efficiency.

Regular Maintenance and Updates

Keeping and upgrading forklift security signs is essential for ensuring that they continue to be efficient and relevant in the workplace. Routine evaluations need to be carried out to assess the problem of safety indicators, as exposure to harsh commercial environments can cause fading, damage, or obsolescence. Indications that are no more readable or that include out-of-date information can significantly weaken safety and security procedures.

It is essential to develop a regular maintenance schedule that includes checking the exposure and quality of all security signs. Any kind of indications that are put on, damaged, or misaligned should be immediately changed or repositioned to preserve their performance. Additionally, as guidelines and safety and security criteria develop, it is essential to update signage to show existing techniques and compliance demands.

Involving workers in safety training sessions can also strengthen the relevance of maintaining and updating safety indications. This not just guarantees that every person is aware of the signs' significances however likewise cultivates a society of safety and security within the workplace. By prioritizing routine upkeep and updates, companies can produce a more secure setting and boost the overall efficacy of their forklift safety and security signage.

Conclusion

Finally, the implementation of best practices for displaying forklift truck safety signs is crucial for boosting workplace security in industrial and my blog stockroom environments. By prioritizing visibility, utilizing effective positioning methods, making sure compliance with policies, and dedicating to routine maintenance, organizations can significantly reduce the threat of mishaps. Such steps not only connect hazards properly yet likewise foster a culture of safety and security that benefits all employees associated with forklift procedures.